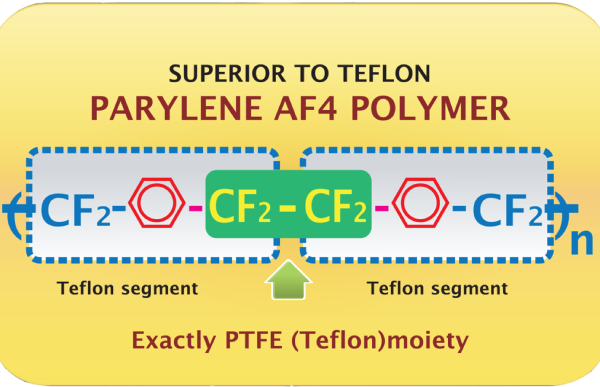

Parylene finds widespread use in various applications like aerospace, automotive, medical, semiconductor, and electric. It is a polymer that is best-suited for conformal coatings because of its inert nature. Parylene is an excellent barrier coating, and therefore, it has rapidly found use in tiny coating parts, for example, circuit board components.Parylene AF4 Polymer is superior to most liquid-based coatings like acrylic or silicone. The parylene is an excellent coating for protecting aerospace PCBs and many other electronic components and assemblies. The encapsulation conforms amazingly on all kinds of device surfaces, including edged services, complex creviced services, flat or round surfaces. Another plus point of the polymer is that the coating does not increase the weight of the coated device in anyways.