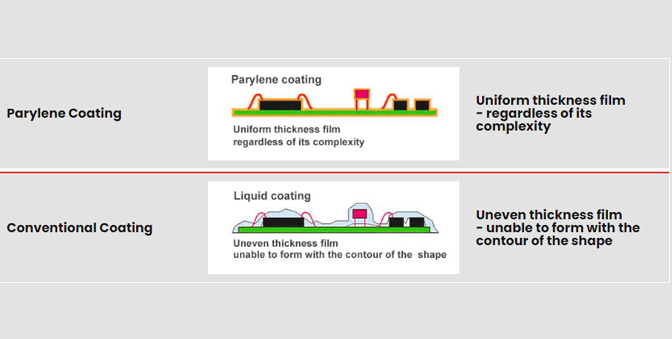

Parylene is the world’s best conformal coating used widely in protective applications. The monomer is coated on the products in the gaseous phase at low pressure. The polymer condenses on the surface by using vacuum deposition in a polycrystalline manner. Thereby, parylene coating is pin-hole-free and exceptionally conformal.

A conventional coating that usually consists of liquid processes comes with surface tension and gravity-related issues, which result in pin-holes, thinning-out, bridging, puddling, running off, and sagging. Also, such coatings need to occur at higher or lower temperatures, putting thermal and mechanical stress on the product surface.

Compared to conventional coating, parylene coating is way more stable physically and chemically inert. Added to this, the parylene coating is moisture-proof, easily bear salt spray, and offers par excellence protection from solvents, contaminants, chemicals, pollutants, and corrosive vapors. The coating is tolerant of all kinds of hostile environments with a friction coefficient as low as 0.25.

Parylene coating does not have pin-holes; there is no bridging or thinning out, sagging, or issues related to thinning or runny consistency. The conventional coating has issues with uniformity, thickness, and stress out. Compared to this, parylene coating is ultra-thin, uniform, and stress-free with excellent mechanical properties.

While conventional coating has coating imperfections, most of the issues can be addressed with the help of parylene coating. Acrylic and Silicone-based coating introduce stress, especially in electrical components during the drying and curing cycles. Compared to this, parylene can easily stretch to at least 200% with no issue of breakage armed with unique flexibility across the widest possible temperature range.

Conventional coating suppliers are available online, offering the best industry-level solution. However, with the growth of parylene coating, the conventional sector has taken a backseat. It is especially true in industries like aerospace and medical, where precision, excellence, and long lifespan are key attributes. Parylene has many features that make it a way more superior coating solution than conventional solutions. Some of the top features have been mentioned below. Industries like automotive, medical, aerospace, etc., need to consider how these features outweigh the negative aspects of the conventional solvents and coating processes.